PSA oxygen generator for hospital O2 generator

Product Video

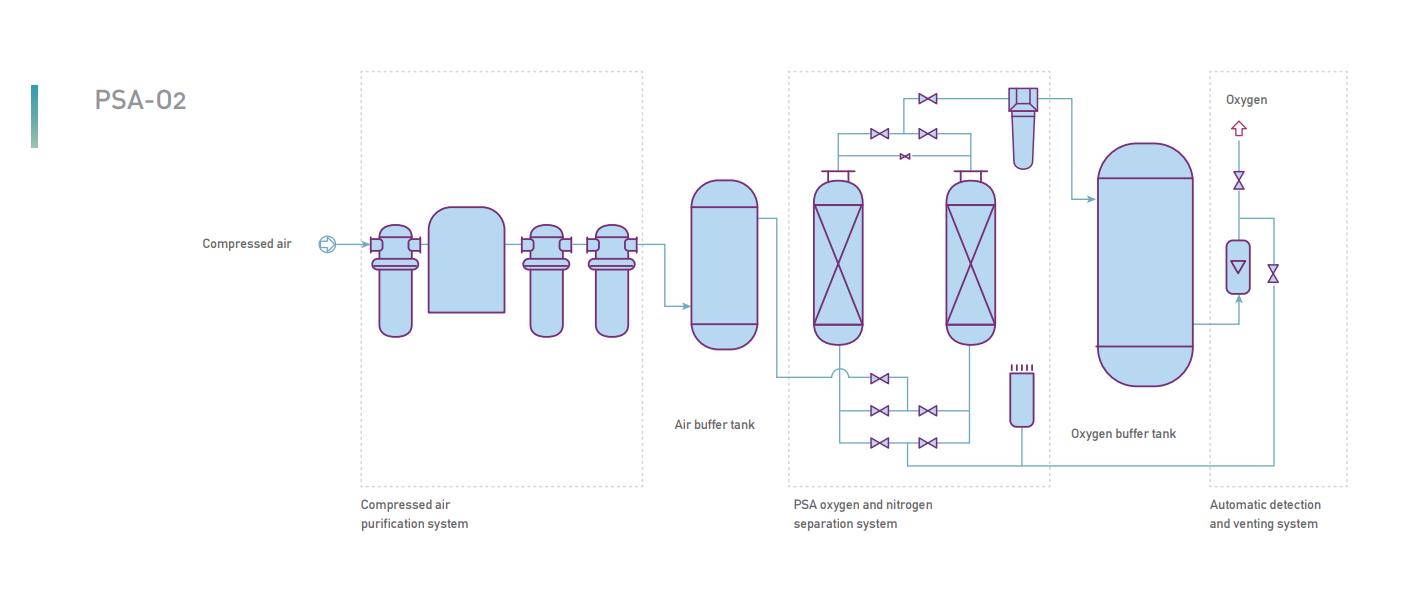

Process

Pressure swing adsorption (PSA) for oxygen production uses air as raw material and carbon molecular sieve as adsorbent. Using the principle of pressure swing adsorption, the carbon molecular sieve filled with micropores selectively adsorbs gas molecules and obtains 90%-93% oxygen.

The pressure swing adsorption equipment mainly consists of two adsorption towers with carbon molecular sieves A and B and control systems equipped. When compressed air (typically 0.8 MPa) passes through the A column from bottom to top, oxygen, carbon dioxide and moisture are adsorbed by the carbon molecular sieve, while nitrogen is passed through and flows out of the top of the column. When the molecular sieve in the A column is saturated, it is switched to the B column to carry out the above adsorption process and simultaneously regenerate the A column molecular sieve. The regeneration, that is, the gas in the adsorption tower is vent to the atmosphere to rapidly reduce the pressure to atmospheric pressure, and then the oxygen, carbon dioxide and water adsorbed by the molecular sieve are released from the molecular sieve.

Technical characteristics

Our company has always been based on customer service, focus on technical innovation and energy efficiency improvement, continuous breakthrough optimization design, never stop the pursuit of quality, give SPO energy-saving oxygen generator stable and reliable, efficient production, energy saving and environmental protection and other excellent quality, technical level in the industry leading position.

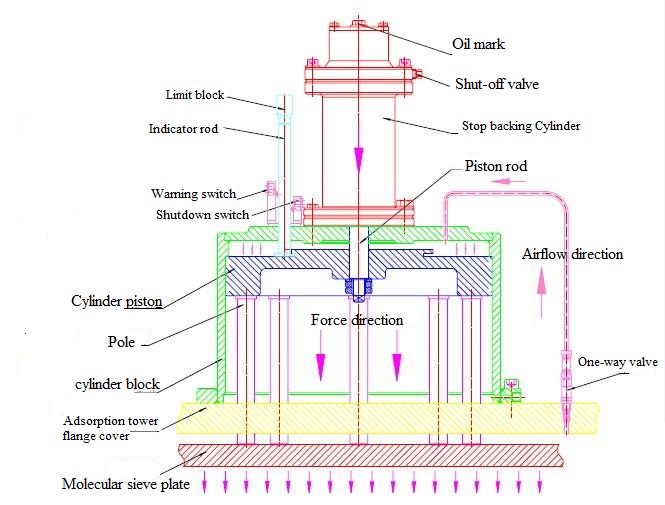

Self-developed compression device, excellent protection ability

The adsorption tower adopts self-made, patented self-operated cylinder compression technology. In the inner bed of the separation tower, since the molecular sieve is a granular material, it is impossible to fill the absolute density during the filling process, so that during the working process, under the impact of the airflow, there is mutual friction between the molecular sieves. It leads to the possibility of powdering and sinking, so it is necessary to have a device that can step by step to compensate for the vacancy caused by sinking. In today's compacting devices, there are generally three types of cylinder compression, spring compression (some of which are also pressed by a coconut shell pad) and airbag compression.

The force of spring compression follows Hooke's law: F = K (X0-X), and its pressing force is inversely proportional to the stroke (spring length X). For the spring compression mechanism, two points must be identified: the maximum compressive strength of the molecular sieve and the minimum pressure of the compacted molecular sieve, and then according to these two points to select the spring specification, initial compression and stroke, slightly different, It is possible that the molecular sieve is crushed due to the large amount of initial compression or the pressure is not tight due to the increase in stroke.

The airbag is pressed tightly, and is generally used in the case where the cylinder or the spring cannot be used. It has great disadvantages: 1. The working state of the airbag cannot be monitored, 2. The material of the airbag itself is aged. However, compared with other compacting devices, it has a great advantage that the shape of the pressed object can be irregular and suitable for some special occasions.

Our company uses cylinder clamping device, its advantages are:

(1) The pressing force (F=PS) is related to the adsorption pressure and the piston area of the cylinder, and has nothing to do with other factors. In the adsorption separation process, the adsorption pressure is constant, and the piston area is fixed after the completion of the manufacture, so the cylinder The pressing force is a constant force that does not change with the stroke.

(2) The stroke of the cylinder can be measured or sensed externally, and the alarm point can be set in advance.

(3) The required gas of the cylinder is directly taken from the separation tower, and can be operated synchronously with the separation tower at any time to realize dynamic compaction.

The cylinder is compressed by the air source of the adsorption tower itself. When the nitrogen generator starts working, it enters the working state. The internal piston always ensures the molecular sieve is compacted, and at the same time does not crush the molecular sieve, which can avoid the adsorption/analysis of different airflow inside the adsorption tower, the impact of the airflow causes the molecular sieve to chalk. Extend the service life of the molecular sieve. The pressing device is equipped with a settlement alarm system. When the stroke of the compression system exceeds the set stroke limit, the cylinder indicator rod contacts the alarm sensor, the alarm contact is closed, and the PLC receives the input signal and automatically emits an audible and visual alarm to remind the user the molecular sieve has reached the lower limit and need to add it in time.

If the user fails to add the molecular sieve in time, the cylinder continues to work. When the compression system stroke exceeds the set limit stroke, the cylinder indicator rod contacts the stop sensor, the stop contact closes, and the PLC receives the input signal and automatically emits sound and light alarm and stop automatically. Because the compressed gas has a certain compressibility, the cylinders arranged on some large equipment are equipped with a check cylinder. The function of the check cylinder is to use the incompressibility of the hydraulic oil to check the cylinder stroke to ensure the stability of the entire compaction device. The cylinder pressing device is pressed against the spring, the coconut mat is pressed tightly, and the airbag type pressing device is more reliable, the disassembly is more convenient, and the automation is higher.

Specification

|

Model |

O2 Capacity(Nm3/h) |

Effective air consumption |

Air purification system |

|

SPO-5 |

5 |

1 |

KJ-1 |

|

SPO-10 |

10 |

2 |

KJ-3 |

|

SPO-20 |

20 |

4 |

KJ-6 |

|

SPO-40 |

40 |

8 |

KJ-10 |

|

SPO-60 |

60 |

12 |

KJ-12 |

|

SPO-80 |

80 |

16 |

KJ-20 |

|

SPO-100 |

100 |

20 |

KJ-20 |

|

SPO-150 |

150 |

30 |

KJ-30 |

|

SPO-200 |

200 |

40 |

KJ-40 |

|

1. The data listed in the above table are based on the raw material compressed air pressure of 0.8MPa (gauge pressure), the ambient temperature of 38°C, 1 standard atmospheric pressure and 80% relative humidity as the design basis. 2. If the model is not involved in the above table or the design conditions are changed, please consult our company for detailed information. |

|||