Industrial oxygen plant O2 plant

Product Video

Process

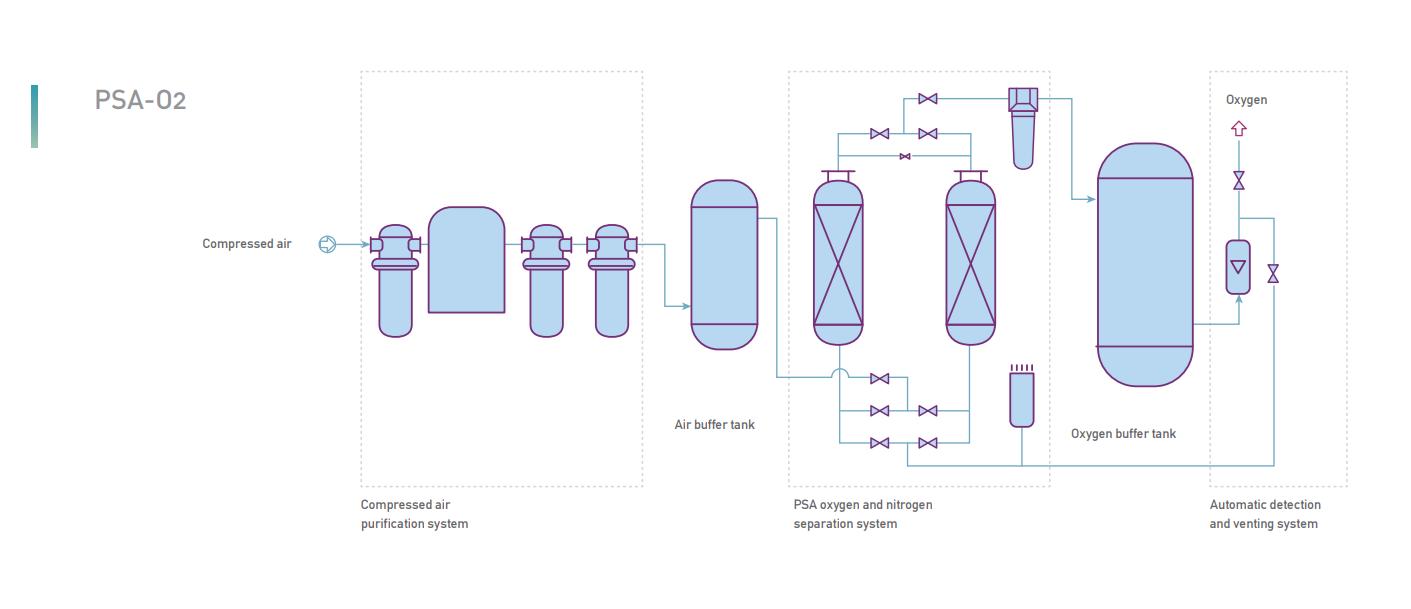

Pressure swing adsorption (PSA) for oxygen production uses air as raw material and carbon molecular sieve as adsorbent. Using the principle of pressure swing adsorption, the carbon molecular sieve filled with micropores selectively adsorbs gas molecules and obtains 90%-93% oxygen.

The pressure swing adsorption equipment mainly consists of two adsorption towers with carbon molecular sieves A and B and control systems equipped. When compressed air (typically 0.8 MPa) passes through the A column from bottom to top, oxygen, carbon dioxide and moisture are adsorbed by the carbon molecular sieve, while nitrogen is passed through and flows out of the top of the column. When the molecular sieve in the A column is saturated, it is switched to the B column to carry out the above adsorption process and simultaneously regenerate the A column molecular sieve. The regeneration, that is, the gas in the adsorption tower is vent to the atmosphere to rapidly reduce the pressure to atmospheric pressure, and then the oxygen, carbon dioxide and water adsorbed by the molecular sieve are released from the molecular sieve.

Technical characteristics

Advanced pressure equalization technology improves performance and reduces loss

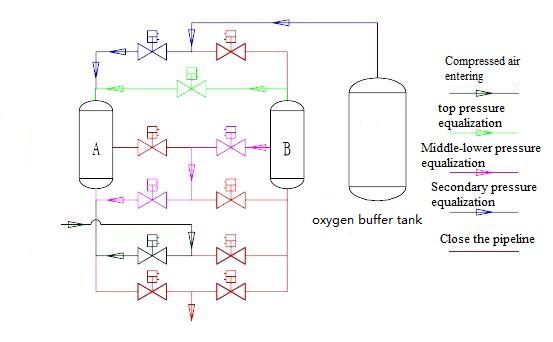

In the PSA oxygen production process, pressure equalization is an important process. The adsorption tower needs to pressure equalization before the end of one adsorption cycle to prepare for venting and the other tower to complete the regenerated preparation work.

There are two main functions of pressure equalization: first, let the adsorption tower that has been regenerated reach the adsorption pressure in a short time to improve the efficiency of molecular sieve utilization; second, let the nitrogen-rich gas in the adsorption tower before venting is fully utilized to achieve the purpose of saving energy.

The oxygen production pressure equalization process is divided into three parts: pressure equalization at the top of the conventional pressure equalizing valve; the middle- lower pressure equalization of the middle pressure equalizing gas take-up and pressure equalizing valve with the lower equalizing valve and the secondary pressure equalization of the nitrogen buffer tank to the adsorption tower.

The advanced pressure equalization process enables the regenerated tower to reach the adsorption pressure in the shortest time and minimizes the partial pressure of oxygen in the adsorption tower, which greatly improves the efficiency of molecular sieve utilization and reduces the loss of feed gas.

Specification

|

Model |

O2 Capacity(Nm3/h) |

Effective air consumption |

Air purification system |

|

SPO-5 |

5 |

1 |

KJ-1 |

|

SPO-10 |

10 |

2 |

KJ-3 |

|

SPO-20 |

20 |

4 |

KJ-6 |

|

SPO-40 |

40 |

8 |

KJ-10 |

|

SPO-60 |

60 |

12 |

KJ-12 |

|

SPO-80 |

80 |

16 |

KJ-20 |

|

SPO-100 |

100 |

20 |

KJ-20 |

|

SPO-150 |

150 |

30 |

KJ-30 |

|

SPO-200 |

200 |

40 |

KJ-40 |

| 1. The data listed in the above table are based on the raw material compressed air pressure of 0.8MPa (gauge pressure), the ambient temperature of 38°C, 1 standard atmospheric pressure and 80% relative humidity as the design basis. 2. If the model is not involved in the above table or the design conditions are changed, please consult our company for detailed information. |

|||