Green Hydrogen Generator Via Water Electrolysis

Product Video

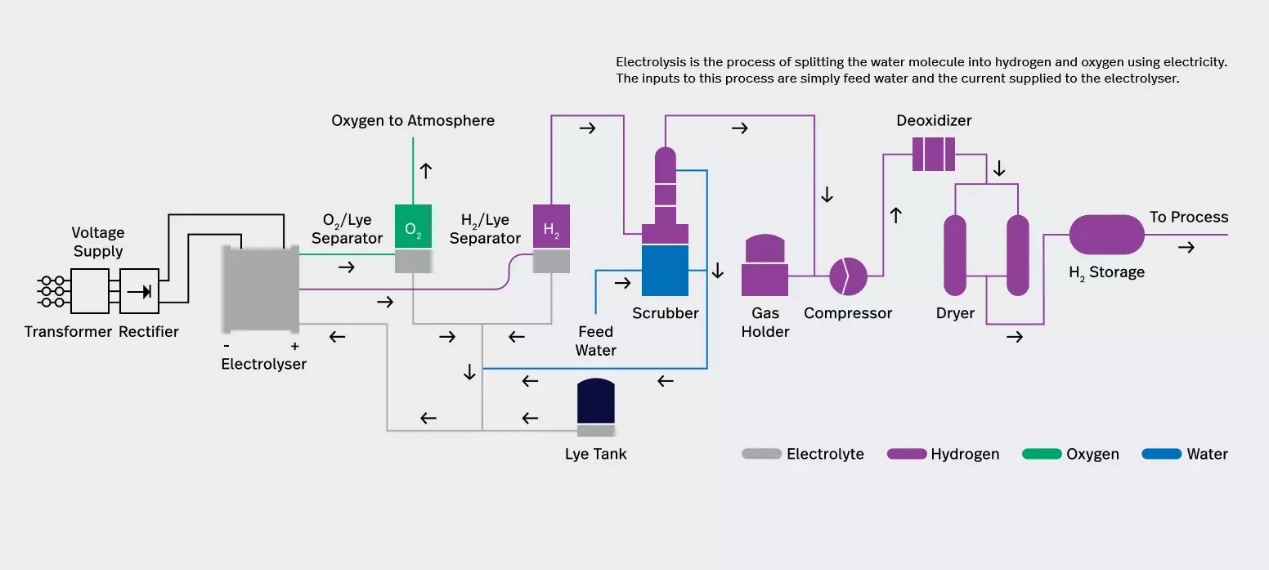

Working Principal

The equipment use water electrolysis to generate pure hydrogen and pure oxygen. By controlling the liquid level of hydrogen / oxygen tank, to ensure the hydrogen purity. It will go through the processes such as hydrogen washing, gas / liquid separation and cooling process to finally produce hydrogen.

Apply Scope

CHO series hydrogen equipment uses water electrolysis to generate pure hydrogen and pure oxygen. It makes hydrogen outlet purity up to 99.8%and hydrogen outlet pressure up to 4.0Mpa. This equipment suits for lower requirements for hydrogen purity. We can make the appointed hydrogen equipment according to the client's needs.

Structure Characteristics

1. Electrolytic tank: applying brand-new structure design to have lower electrode voltage, higher current density and lower energy consumption of hydrogen unit production.

2. Gas / liquid separator: simplifies the previous product structure, makes space smaller and better effects of gas / liquid separator.

3. Explosion-proof design: all the parts are designed as explosion-proof. Clients can choose the appointed brand parts if they required.

4. Cabinet: one integrated cabinet, containerizing or disassemble according to the client's requirements. Note: Model below CHO-100, the equipment can be designed in containerizing cabinet. Model above CHO-100, the electrolytic tank needs to be placed alone and gas / liquid separator can be designed in containerizing cabinet.

Specification

| MODEL | H2 Capacity

Nm3/h |

H2 purity | O2 purity | Current

(A) |

DC

(V) |

Working temperature | Pressure |

| CHO-1 | 1 | 99.8% | 99.3% | 200 | 26 | ≤85℃ | ≤0.6MPa |

| CHO-4 | 4 | 99.8% | 99.3% | 320 | 62 | ≤85℃ | |

| CHO-6 | 6 | 99.8% | 99.3% | 760 | 40 | ≤85℃ | |

| CHO-12 | 12 | 99.8% | 99.3% | 760 | 78 | ≤85℃ | |

| CHO-15 | 15 | 99.8% | 99.3% | 1240 | 60 | ≤85℃ | |

| CHO-20 | 20 | 99.8% | 99.3% | 1240 | 82 | ≤85℃ | |

| CHO-30 | 30 | 99.8% | 99.3% | 1240 | 118 | ≤85℃ | |

| CHO-50 | 50 | 99.8% | 99.3% | 1800 | 130 | ≤85℃ | |

| CHO-80 | 80 | 99.8% | 99.3% | 4600 | 86 | ≤85℃ | |

| CHO-100 | 100 | 99.8% | 99.3% | 4600 | 106 | ≤85℃ | |

| CHO-120 | 120 | 99.8% | 99.3% | 4600 | 125 | ≤85℃ | ≤1.6MPa |

| CHO-150 | 150 | 99.8% | 99.3% | 4600 | 158 | ≤85℃ | |

| CHO-180 | 180 | 99.8% | 99.3% | 6600 | 136 | ≤85℃ | |

| CHO-200 | 200 | 99.8% | 99.3% | 6600 | 148 | ≤85℃ | |

| CHO-250 | 250 | 99.8% | 99.3% | 6600 | 184 | ≤85℃ | |

| CHO-300 | 300 | 99.8% | 99.3% | 6600 | 220 | ≤85℃ | |

| CHO-350 | 350 | 99.8% | 99.3% | 8200 | 206 | ≤85℃ | |

| CHO-400 | 400 | 99.8% | 99.3% | 8200 | 236 | ≤85℃ | ≤3.2MPa |

| CHO-500 | 500 | 99.8% | 99.3% | 10500 | 230 | ≤85℃ | |

| CHO-600 | 600 | 99.8% | 99.3% | 10500 | 276 | ≤85℃ |