Container type oxygen generator Medical oxygen plant

Product Video

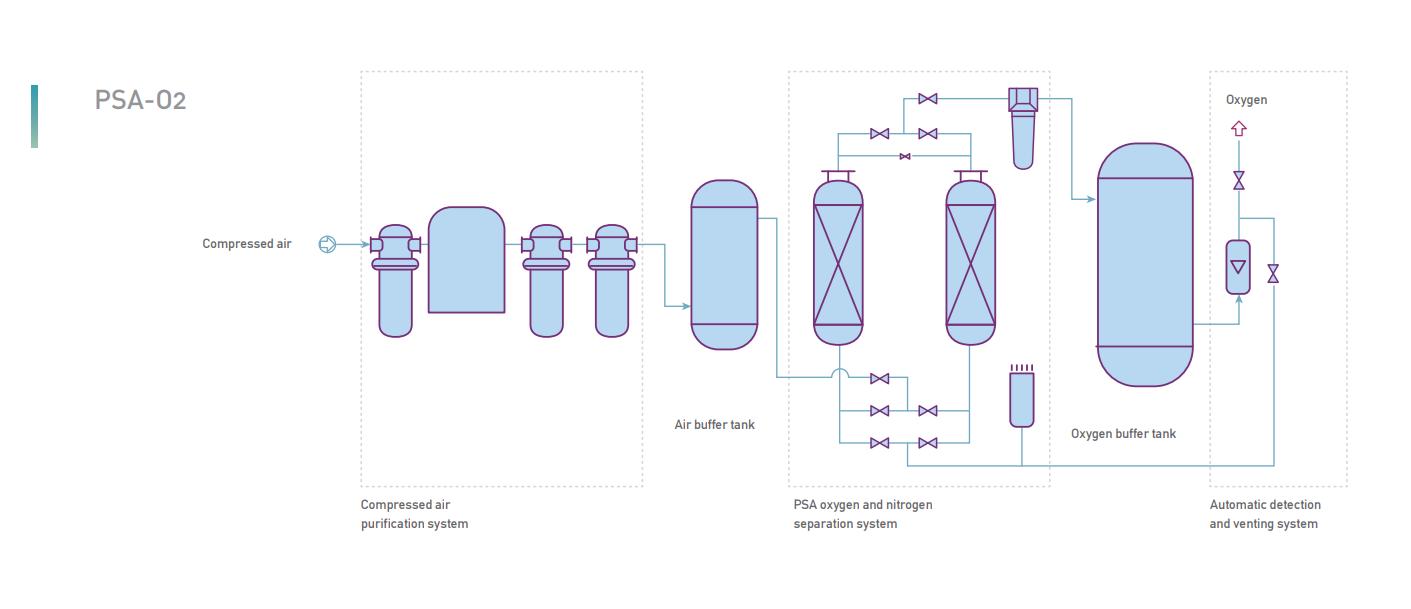

Process

The compressed air passes through the air purification system to remove the impurities, such as oil, water and dust, and into the adsorption tower with zeolite molecular sieve. The nitrogen, carbon dioxide and water vapor in the air are adsorbed in large quantities by molecular sieves, and oxygen and nitrogen are separated because of the high diffusion rate of oxygen.

When the nitrogen and other impurities in the adsorption tower reach saturation, the pressure is reduced and the zeolite molecular sieve is regenerated and reused. The two adsorption towers are operated under the control of PLC and continuously produce high quality oxygen.

Technical characteristics

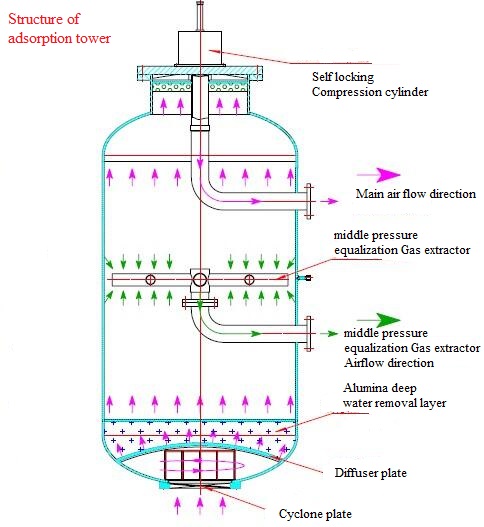

Adopts labyrinth type air diffuser:

The simple, efficient and reliable airflow diffuser solves the industrial problem of uneven airflow distribution in the separation tower.

The divides make the inlet gas direction diffusion in three stages: Firstly, the airflow is firstly deflected by the cyclone, and the airflow direction is changed from straight through to spiral at the inlet of the adsorption tower, which can diffuse the airflow around the adsorption tower and prolong the passage time of the airflow in the adsorption tower (Adsorption time). Then, after the diffusion of the diffuser, it is further refined and uniformly diffused in all directions of the adsorption tower; Finally, through the uniform gap of alumina, the three-stage diffusion is carried out to achieve the desired diffusion effect and then pass through the separation tower bed, make the utilization rate of the molecular sieve become maximized, and the gas production efficiency of the equipment is greatly improved.

The function of alumina

(1) Because of its high strength, it can prevent direct damage of the molecular sieve by the inlet airflow, and protect and extend the service life of the molecular sieve.

(2) Because it is active, it can also absorb impurities such as moisture and oil mist in the inlet airflow to prevent the molecular sieve from being contaminated and prolong its service life and adsorption performance.

(3) Because of its large particle diameter, it is difficult to leak from the sealing edge of the lower edge of the separation tower, so that the molecular sieve loaded on it can be prevented from leaking directly contacting the sealing portion, thereby functioning to isolate and seal the molecular sieve.

(4) Since the particles are uniform and large, a large amount of uniform gap is formed after the accumulation, so that the airflow passes through it to obtain further uniform diffusion.

Central air extractor

In order to maximize the amount of “semi-finished” gas remaining in each separation cycle in the separation tower to be reused in the next separation cycle, to reduce waste and energy consumption, we adopted the “root” type central gas extraction structure. The structure can collect the remaining gas in the tower through a "root" type branch pipe in a multi-directional, large-area, uniform, rapid and efficient manner, and finally collects into the "total branch" and enter another tower for cycle recycling.