Container Type Natural Gas Steam Hydrogen Production Plant H2 Plant Hydrogen Generator

Process

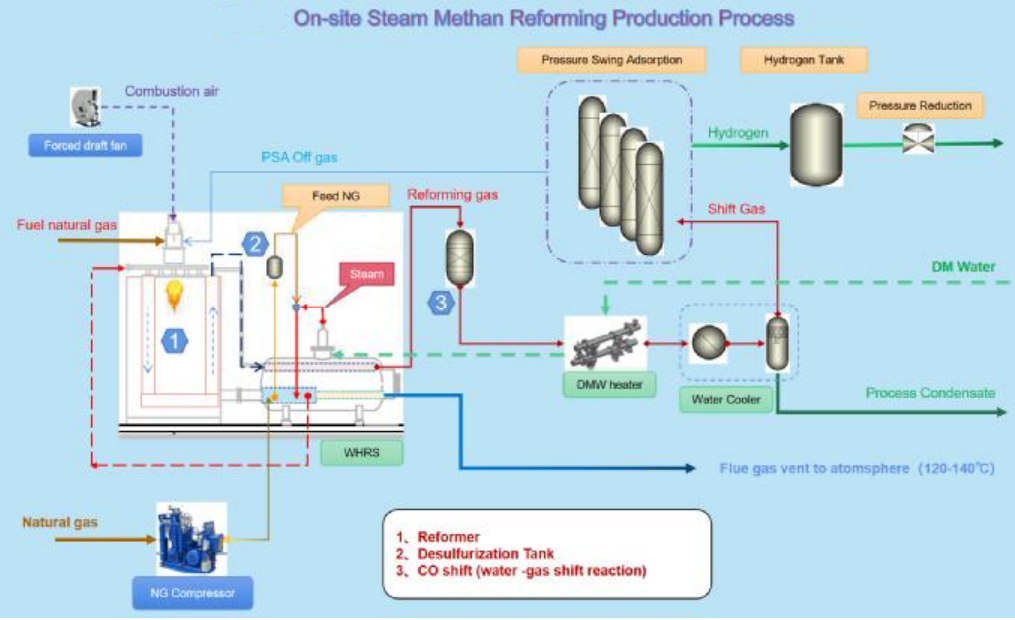

Steam-Methane Reforming(SMR):

1) A mature production process in which high-temperature steam (700°C-900°C) is used to produce hydrogen from a methane source, such as natural gas. Methane reacts with steam under 8-25 bar pressure (1 bar = 14.5 psi) in the presence of a catalyst to produce H2\CO\CO2. Steam reforming is endothermic-that is,heat must be supplied to the process for the reaction to proceed.Fuel natural gas and PSA off gas are used as fuel.

2) Water-gas shift reaction, the carbon monoxide and steam are reacted using a catalyst to produce carbon dioxide and more hydrogen.

3) In a final process step called "pressure-swin adsorption(PSA)," carbon dioxide and other impurities are removed from the gas stream, leaving essentially pure hydrogen.

Features

Compact design suitable for on-site hydrogen supply

Compact design withe less thermal and pressure losses.

A package makes its installation on-site very easy and quickly.

High-purity hydrogen and Dramatic cost reduction

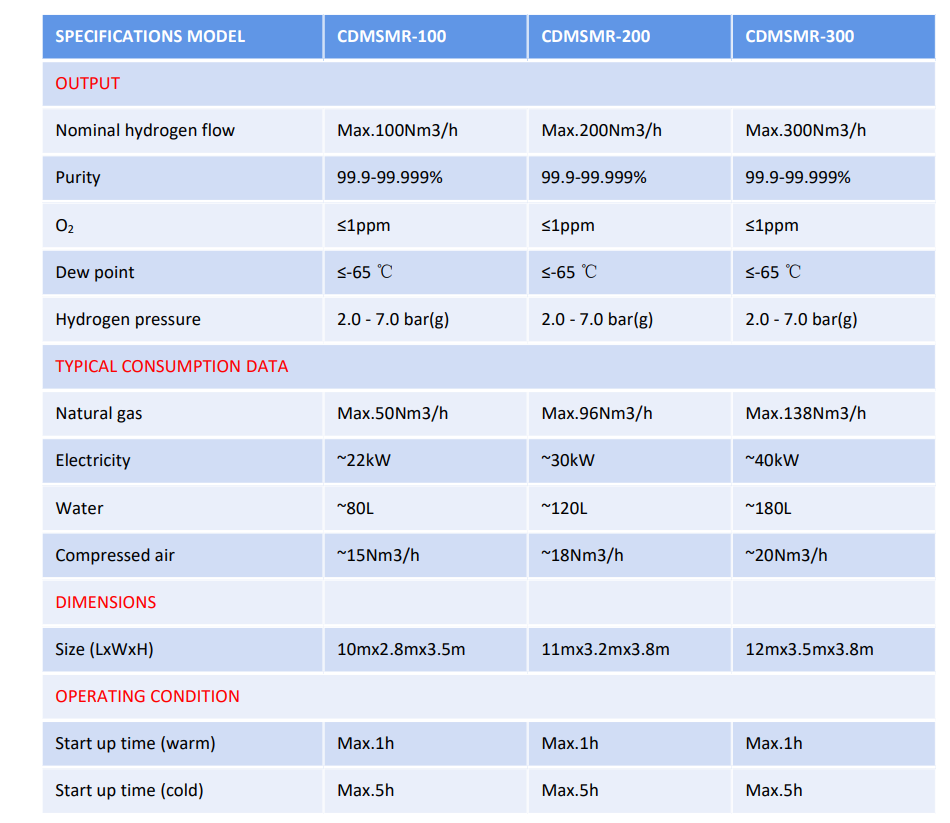

The purity can from 99.9% up to 99.999%.

The Natural gas(including the fuel gas) can as low as 0.40-0.5 Nm3 -NG/Nm3 -H2.

Easy operation

Automatic operation by one button start and stop.

Load between 50 to 110% and hot standby operation are available.

Hydrogen is produced within 30 minutes from the mode of hot standby.

Optional functions

Remote monitoring system, remote operating system, and etc.